Closeddie forging—also known as impression die forging—is a highly productive metal shaping process in which heated metal is worked inside the closed dies to manufacture parts of a definite shape and having good mechanical properties. By forging metal inside a pre-planned die cavity, closed die forging provides a means for producing parts near-net or net-shape with higher strength, better repeatability, and greater dimensional accuracy. As such, the process is a good fit for parts that must perform reliably and be safe.

Closed Die Forging Meaning and Closed Die Forgings Overview

The fundamental principle of closed die forging is that the metal is trapped between the two halves of the die and the material flows along the path of least resistance during deformation. In open die forging, there are usually only two surfaces that restrict the metal, so a much wider variety of shapes can be produced. Closed die forgings can make complex shapes that have a very uniform structure and very predictable performance because the material lay is tightly controlled. Industries like the automotive industry, Wind Power Forgings,Steam Turbine Forgings,Nuclear and Defense Industry Forgings,Mining Machinery Forgings,Metallurgical Machinery Forgings,Marine Forgings,Pipe Mold Forgings,Oil & Gas And Petrochemical Forgings,Pressure Vessel Forgings,Hydraulic Transmission Forgings,Hydro and Thermal Power Forgings,are major users of the closed die forging process as it guarantees consistency in the part’s shape and strength.

Closed Die Forging Process and Closed Die Forging Process Steps

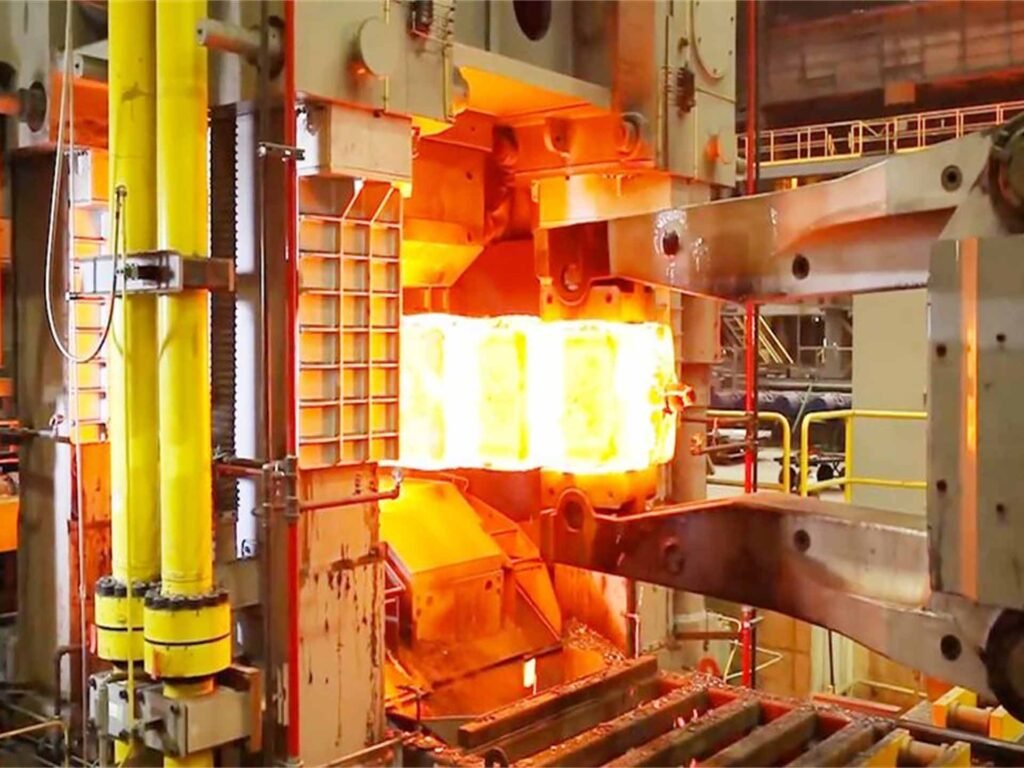

The closed die forging process has step by step operations that result in the fine microstructure of the steel and the finished part with the best dimensions and properties. In order to make the billet malleable, it is heated up to the desired temperature for forging. Then a first operation called preforming causes the billet to roughly assume the shape of the die cavity of the final operation. Finally, the piece is forged in the closed die cavity. After forging trimming of the flash is carried out and then the forging is subjected to heat treatment in order to reach the optimal combinations of strength, toughness, and resistance to fatigue. The final mechanical properties are determined by each step of the closed die forging process steps.

Closed Die Forging Press, Closed Die Forging Hammer, and Press Forging Methods

Depending on the workpiece or the metal to be worked, either a hammer or press can be used in closed die forging. A hammer that is used for impression die forging can transfer high impact energy in a very short time, and it is thus suitable for the production of small parts and undercuts in which rapid metal flow is advantageous. On the other hand, a press used for impression die forging exerts a slow pressing force that is controlled thus a better deformation control and dimensional accuracies can be achieved. The use of closed die press forging is mostly associated with big parts and hard-to-forge materials where the internal soundness and the consistency of the microstructure are of paramount importance.

Closed Die Forged Steel and Closed Die Aluminum Forging Materials

A wide range of metals can be processed through closed die forge operations. Closed die forged steel, including carbon steel, alloy steel, and stainless steel, is widely used for high-load and pressure-bearing components. Closed die aluminum forging is selected when weight reduction and corrosion resistance are priorities. The closed die forging process aligns the internal grain flow with the part geometry, resulting in superior mechanical performance compared to cast or machined-from-plate components.

Closed Die Forging Advantages and Disadvantages in Industrial Manufacturing

Understanding closed die forging advantages and disadvantages is important when selecting a manufacturing method. Closed die forging offers excellent dimensional consistency, repeatable mechanical properties, and reduced machining requirements, making it ideal for medium to high production volumes. However, the need for dedicated tooling results in higher initial costs, which may not be suitable for very low-volume or oversized components. Despite this, the long-term performance and efficiency benefits often outweigh the tooling investment.

Closed Die Forged Parts Applications Across Key Industries

Closed die forged parts are commonly used in applications where reliability under cyclic loading and high stress is required. Automotive drivetrain components, oil & gas valve bodies, aerospace structural elements, and industrial machinery parts all benefit from the refined grain structure produced by closed die forging. The controlled deformation ensures consistent performance even in demanding operating environments.

Closed Die Forging Products Manufactured by TIP TOP Forging

In practical production, closed die forging at TIP TOP Forging is applied to manufacture a wide range of industrial components that require high strength, dimensional consistency, and reliable internal structure. Typical closed die forged parts include forged blocks, flanges, valve bodies, hubs, stepped shafts, and custom-shaped mechanical components produced according to customer drawings and application requirements.

These closed die forged steel and alloy components are commonly supplied for oil & gas equipment, industrial machinery, pressure-bearing systems, and power transmission assemblies. Depending on the application, materials may include carbon steel, alloy steel, stainless steel, aluminum alloys, and nickel-based alloys, all processed through controlled closed die forging process and subsequent heat treatment to ensure stable mechanical performance.

Closed Die Forging Process Control and Quality Considerations

The success of closed die forging depends heavily on process control. Factors such as forging temperature, deformation ratio, die design, lubrication, and heat treatment must be carefully managed to avoid internal defects and ensure consistent quality. Proper control throughout the forging cycle results in closed die forgings with stable mechanical properties and long service life.

TIP TOP Forging: Professional Closed Die Forging Manufacturer

TIP TOP Forging is dedicated to providing closed die forging solutions of superior quality to industrial customers worldwide. With expertise in carbon steel, alloy steel, stainless steel, aluminum, and nickel-based alloys, we turn out closed die forged parts that satisfy the most stringent technical specifications. Forging by press or hammer is our practice at different times and we adjust the method to the nature of the material and the application to get the optimum result.

Closed Die Forging vs Open Die Forging: Which is better?

Open die forging can still be used for very large or simple shapes. However, when it comes to component design, tolerance control, and repeatability, closed die forging undoubtedly has the upper hand. By having detailed discussions with the customers, TIP TOP Forging identifies the best option between closed die forging and open die forging for achieving an ideal combination of performance, cost, and manufacturability.

In summary, closed die forging is an excellent method for manufacturing components that require precision and strength to last a long time.

Closed die forging presents a reliable method of manufacturing components that have excellent strength, are designed with high precision, and have great mechanical integrity. Whether it is closed die forged steel or closed die aluminum forging, the technique guarantees excellent quality and dependable performance in various industries. TIP TOP Forging combines technical know-how and controlled manufacturing processes to work closely with customers and provide them with reliable closed die forging solutions that are appropriate for their needs.