SA182 F316L Forged Ring – A Corrosion-Resistant Austenitic Stainless Steel Forgings

SA182 F316L forged ring is the one of the series austenitic stainless steel forging with low-carbon S31603 being the UNS number that identifies this material. Because of its improved corrosion resistance and weldability, F316L forged rings find extensive application as high-quality semi-finished products from which the next generation of the most demanding circular components working in corrosive and high-pressure environments is made.

Description

What Is SA182 F316L Forged Ring?

SA182 F316L forged ring is the one of the series austenitic stainless steel forging with low-carbon S31603 being the UNS number that identifies this material. Because of its improved corrosion resistance and weldability, F316L forged rings find extensive application as high-quality semi-finished products from which the next generation of the most demanding circular components working in corrosive and high-pressure environments is made.

Material Characteristics of SA182 F316L

An Ultra-Resistant Stainless Steel

The SA182 F316L benefits from an elevated content of chromium, nickel, and molybdenum, which makes it the material of choice for such applications as:

- Chloride environments

- Acids and chemical media

- Pitting and crevice corrosion

Compared with 304 stainless steel, 316L forged stainless steel has better resistance to corrosion when used in seawater and chemical processing applications.

The Low Carbon Advantage

With a carbon content of no more than 0.030%, SA182 F316L is able to significantly lower the occurrence of carbide precipitation in the area of the weld during the welding operation or if the material is exposed to high temperatures.

Some of the benefits are:

- Lower sensitivity to intergranular corrosion

- Improved weldability

- Higher structural stability at elevated temperatures

316L welding structures, therefore, are more long-lasting and trustworthy in the presence of any form of corrosion and in offshore environments.

Reliable Mechanical Properties

Typically the mechanical properties of the material in the solution-treated condition are:

- Tensile strength ≥ 70 KSI

- Yield strength ≥ 25 KSI

- Elongation ≥ 40%

Such mechanical properties are the reason why F316L forged rings would be capable of handling scenarios of high loads, vibration, and repeated industrial service stresses.

Why Forged Rings Instead of Rolled or Cast Parts?

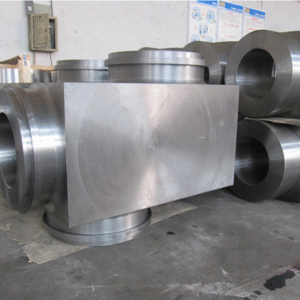

SA182 316L forged rings cannot be considered end products. These are non-machined high-strength ring blanks of the semi-finished material that are destined to be further machined into the final components.

Forging benefits:

- Refined grain structure

- Eliminated internal defects

- Higher fatigue strength

- Stable mechanical behavior under pressure

Common end-use products include:

- Flanges

- Bearing rings

- Gear rings

- Turbine rings

- Sealing rings

High-pressure pipe system components

Applications of SA182 F316L Forged Rings

General Industrial Piping

Used in corrosive pipeline systems where reliability is essential:

- Chemical piping

- Oil & gas transportation

- Heat exchanger connections

- Pump casings and valve components

Marine & Offshore Equipment

316L forged stainless steel offers high resistance to seawater corrosion, suitable for:

Shipbuilding

Offshore platforms

Marine pumps and valves

Propulsion systems

Power Generation Industry

F316L forged rings are widely used in:

Wind power equipment

Nuclear power plants

Steam turbines and compressors

These components operate under high stress and corrosive environments, requiring material integrity and long-term durability.

Standards & Supply Capabilities

We manufacture SA182 F316L forged rings according to international standards:

ASTM A182 / ASME SA182

UNS S31603

EN / DIN / JIS equivalents

Available forms:

Rolled rings

Seamless forged rings

Large diameter forged rings

Typical supply range:

OD: 200 mm – 3000 mm

Thickness: customizable

Machining: CNC finish machining available

Other stainless steel forged products:

- 316L forged flanges

- 316L forged fittings

- 316L forged shafts

- Custom stainless steel forgings

Advantages of Choosing SA182 F316L Forged Rings

✔ Excellent corrosion and pitting resistance

✔ Low-carbon formula for improved weldability

✔ High strength with reliable ductility

✔ Ideal for offshore, chemical, and power applications

✔ Customizable sizes and machining according to drawings

Conclusion

SA182 F316L forged ring is an excellent forging choice that provides the benefits of increased corrosion resistance, reduced carbon content, and good mechanical properties. Due to these characteristics, it is used extensively in the aforementioned fields of application that include: power generation, marine equipment, petrochemical plants, and sophisticated industrial machinery, where the requirement of stability and operational safety over a long period is needed.

We supply forged products that meet the quality standards needed for reliable industrial projects, along with material certification and quick delivery.