A105 T-Slot Flange: High-Pressure Precision

In critical industrial piping systems, seal integrity is everything. The A105 T-Slot Flange is a specialized forged carbon steel connector designed for high-pressure and high-temperature environments. By combining the robust mechanical properties of ASTM A105 Carbon Steel with a precision-engineered T-Slot Ring Joint Face (RJF), this flange offers a superior solution for challenging connections where standard flat-faced flanges fail.

Description

In critical industrial piping systems, seal integrity is everything. The A105 T-Slot Flange is a specialized forged carbon steel connector designed for high-pressure and high-temperature environments. By combining the robust mechanical properties of ASTM A105 Carbon Steel with a precision-engineered T-Slot Ring Joint Face (RJF), this flange offers a superior solution for challenging connections where standard flat-faced flanges fail.

What is an A105 T-Slot Flange?

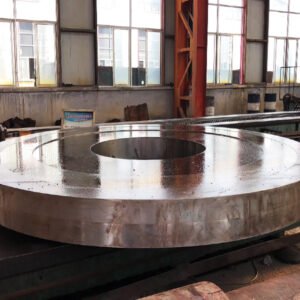

This product is an evolution of the traditional Ring Type Joint (RTJ) flange. It is manufactured using premium ASTM A105 carbon steel forging techniques, ensuring a dense, defect-free metal structure.

The defining feature is the “T-Slot” groove machined into the flange face. Unlike standard sealing surfaces, this groove is designed to house a solid metal ring gasket (typically octagonal or oval). This design is not just about connecting pipes; it is about creating a “self-energizing” seal that actually gets tighter as internal pressure increases.

Why Choose the T-Slot Design? Key Advantages

For engineers and installation teams, the T-Slot design solves specific operational headaches found in heavy industry.

Precision Gasket Alignment: The T-Slot is a guide and retainer. The slot during a vertical pipe or hard-to-reach area installation operation essentially holds the metal ring gasket against the flange body. Before the bolts are tightened, the gasket can thus neither slip nor drop out, which result in the assembly process being much easier.

Superior “Self-Energizing” Sealing: This is the most important factor for high-pressure lines. As the internal pressure of the fluid or the gas increases, it forces the metal gasket to the outside of the T-Slot by the angled walls. So the seal keeps getting tighter with increasing pressure.

Extreme Durability: The soft gaskets which are used as sealing means in our day-to-day applications normally get degraded, however, the metal-to-metal type of seal created by the T-Slot arrangement is not only resistant to blowouts but also to high temperatures and corrosive chemicals.

Reusability: The metal ring gaskets in these flanges are very strong. On condition that the groove is not harmed while breaking down the flange, it is often possible to re-seal the connection and thus, the investment stays longer.

Material Excellence: ASTM A105 Forged Steel

At TIP TOP, we don’t simply make flanges by machining; we create them by forging. We make use of ASTM A105 which is recognized as the highest quality standard for the carbon steel piping components both for ambient and high-temperature services.

Forged Strength: The grain structure of the steel gets realigned with the shape of the flange during our forging operation. That is why the forged flange has higher impact strength and is more resistant to fatigue than the ones made by casting or machining from a plate.

Weldability: A105 steel has a high degree of weldability, hence, it is always possible to get a very strong and permanent weld when joining a pipe and a flange regardless of whether the flange is a Weld Neck one or a Slip-On.

Critical Applications

T-Slot A105 Flange is a solid workhorse in the pipe industry — primarily designed for the applications that simply cannot tolerate leaks:

Oil & Gas Transmission: Perfectly suited for wellhead equipment, manifold, and valves where pressure goes up and down efficiently.

Petrochemical Industry: High-pressure reactors, heat exchangers, and cracking units.

Power Generation: The role is indispensable for the power plant high-temperature steam lines.

Specifications and Manufacturing Standards

We are committed to delivering quality Forged Steel Flanges conforming to international standards thus, enabling easy integration into your existing systems.

Material: Carbon Steel ASTM A105 / A105N

Face Type: T-Slot / Ring Joint Face (RJF)

Pressure Ratings: Class 150 through Class 2500

Sizes: Length and bore sizes can be standard or customized according to requirements.

Why Partner with TIP TOP for Your Flange Needs?

Quality isn’t merely a slogan; it’s how we operate. Being a China-based forging specialist manufacturing factory, with TIP TOP your every order of the A105 T-Slot Flange that is supposed to be the most durable one is a guarantee.

Our work does not end at mere dimensions either. Before shipment, our flanges go through the most thorough Non-Destructive Testing (NDT) to confirm the absence of any micro-defects inside the forged body. Whether you only require a standard unit for replacement or need a tailor-made product for a high-pressure vessel, our engineers will be happy to interact with your project needs.

Get the strength of forged steel for your linkages. Contact Us Today to discuss and/or get a detailed quote on the A105 T-Slot Flanges.