42CrMo Forged Transmission Shaft for Heavy-Duty Mining Applications

42CrMo forged transmission shafts are widely recognized as a core component in heavy-duty mining equipment. With excellent strength, fatigue resistance, and structural integrity, this forged shaft solution is especially suitable for high-torque and high-impact transmission systems such as crushers, conveyors, and mining drives.

Description

42CrMo forged transmission shafts are widely recognized as a core component in heavy-duty mining equipment. With excellent strength, fatigue resistance, and structural integrity, this forged shaft solution is especially suitable for high-torque and high-impact transmission systems such as crushers, conveyors, and mining drives.

Material Selection for Mining Transmission Shafts

Our transmission shafts are manufactured from 42CrMo alloy steel, a proven material for demanding transmission drive shaft applications.

After proper heat treatment, 42CrMo forged shafts achieve:

Tensile strength: 1000–1200 MPa

Yield strength: ≥800 MPa

These mechanical properties make 42CrMo an ideal choice for mining transmission shafts, where continuous heavy loads, shock forces, and long service life are critical.

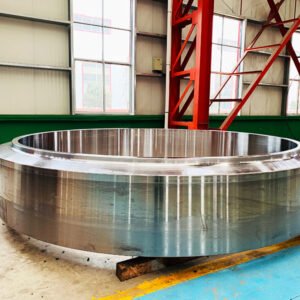

Forging the Shaft for High Torque and Structural Integrity

To meet the extreme torque requirements of mining equipment—such as jaw crusher main shafts and scraper conveyor transmission drive shafts—we adopt free forging technology to form the shaft as a single integral piece.

Shaft diameter range: 500–800 mm

Shaft length: 3–6 m

Length-to-diameter ratio controlled within 8:1 to prevent bending deformation under heavy loads

This approach to forging the shaft ensures superior internal structure compared with welded or cast alternatives.

H2: Optimized Metal Flow in Forged Shafts

During forging, billets are heated to 1150–1200°C to achieve optimal plasticity. Through multiple upsetting and drawing processes, the metal flow lines are aligned along the axial direction of the shaft.

This axial grain flow matches the force direction of the transmission shaft, resulting in:

Over 50% improvement in fatigue resistance compared to cast shafts

Higher resistance to crack initiation under cyclic loads

This is a key advantage of high-quality shaft forgings used in mining environments.

Integral Flange Design for Transmission Drive Shafts

For transmission shafts with flanges, we apply die forging to form the flange and shaft body as a single unit.

Compared with welded flange shafts, this forged shaft structure:

Eliminates weld-related stress concentration

Improves load transfer efficiency

Enhances long-term operational reliability

The transition fillet radius between flange and shaft body is designed to be ≥10 mm, further reducing the risk of fatigue fracture.

Typical Applications of 42CrMo Forged Shafts in Mining

Jaw Crusher Main Transmission Shaft

A typical example is a 42CrMo forged transmission shaft (Ø450 mm × 3.2 m) used as a jaw crusher main shaft:

Withstands crushing forces up to 2000 kN

After 1000 hours of continuous operation, journal wear ≤ 0.03 mm

No visible deformation or structural defects

This performance confirms the suitability of forged shafts for long-term mining transmission systems.

Inspection and Testing Standards for Mining Shaft Forgings

All forged transmission shafts are subjected to strict quality control procedures:

Tensile testing:

Three samples per batch; yield strength must meet ≥800 MPa

100% Ultrasonic Testing (UT):

Internal defects ≥ φ3 mm are strictly prohibited

These inspection standards ensure each forged shaft meets the reliability requirements of mining and heavy industry transmission systems.

Custom Forged Transmission Shaft Solutions for Your Project

Every mining transmission system operates under different loads, speeds, and environmental conditions. Shaft size, forging method, heat treatment, and inspection requirements must be precisely matched to the application.

If you are sourcing a forged transmission shaft, transmission drive shaft, or other customized shaft forgings for mining or heavy machinery, feel free to share your drawings, specifications, or working conditions.

Our engineering team can assist you in selecting the most suitable forging solution to ensure long service life and reliable performance in real operating conditions.

📩 Contact us today to discuss your transmission shaft requirements and receive a technical proposal.