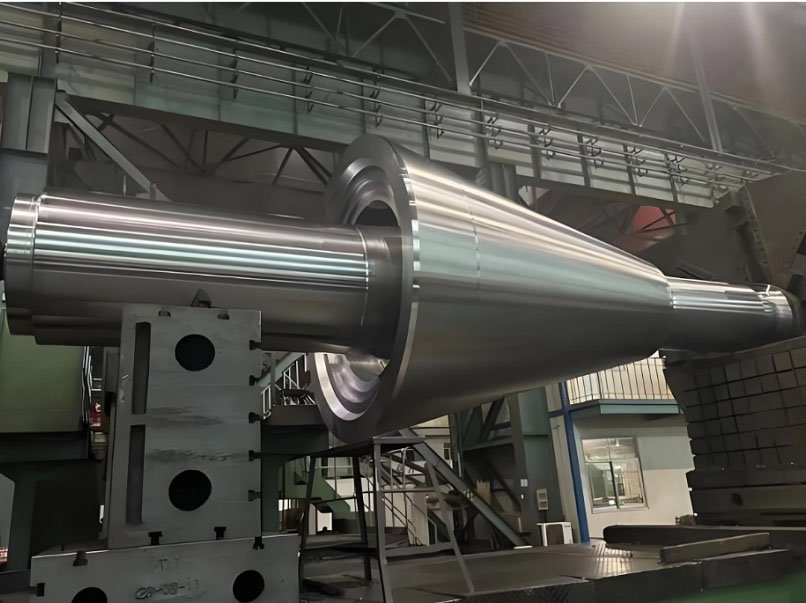

40Cr Main Shaft Forging for Crusher

We choose appropriate steel based on the specific usage requirements and performance characteristics of the main shaft. For instance, for the main shaft of a crusher that is subject to significant impact and torque, medium carbon alloy steel such as 40Cr is often chosen. This type of steel has excellent comprehensive mechanical properties, with both strength and toughness meeting the usage demands of the crusher main shaft under complex working conditions.

Description

Material Selection for 40Cr Crusher Main Shaft Forging

We choose appropriate steel based on the specific usage requirements and performance characteristics of the main shaft. For instance, for the main shaft of a crusher that is subject to significant impact and torque, medium carbon alloy steel such as 40Cr is often chosen. This type of steel has excellent comprehensive mechanical properties, with both strength and toughness meeting the usage demands of the crusher main shaft under complex working conditions.

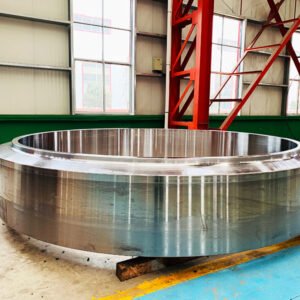

Manufacturing Process of 40Cr Main Shaft Forging

Forging Process for Crusher Main Shaft

Forging: Our main shafts are forged to improve the internal structure of the steel, making it denser and more uniform, and improving the overall mechanical properties of the main shaft. An appropriate forging ratio is used. For example, the steel is heated to a suitable temperature range (typically 1050–1200°C for 40Cr steel), and then subjected to multiple upsetting and drawing operations on forging equipment. Upsetting causes the steel to deform laterally, refining the grain size; drawing elongates the steel axially, improving the fiber structure direction, aligning the fiber structure with the direction of force on the main shaft, and enhancing the load-bearing capacity of the main shaft.

Annealing Treatment for Stress Relief and Machinability

Annealing: After forging, there are significant residual stresses inside the main shaft. To eliminate these stresses and improve the cutting performance of the steel, it will come into annealing process. After this process, the hardness of the main shaft will decrease, which is conducive to subsequent mechanical processing. At the same time, it can stabilize its size and prevent deformation caused by stress release during subsequent processing and use.

Rough Machining of Crusher Main Shaft Forgings

Rough Machining: The main shaft is initially machined using equipment such as lathes and milling machines.

Quenching and Tempering (Q+T) for Mechanical Performance Optimization

Q+T: The rough processed forgings are subjected to quenching and tempering treatment, which can further enhance their comprehensive mechanical properties. After this process, the main shaft achieves a good balance between strength and toughness, meeting the requirements for it to withstand complex loads in the crusher.

Custom 40Cr Main Shaft Forging Solutions for Crushers

We welcome your provision of customized drawings and specifications to meet your unique equipment and operation requirements. Our technical team is always ready to work closely with you, from design review and process validation to final inspection, to ensure that the forged spindle is fully compatible with the load characteristics, assembly interface and service environment of your crusher.