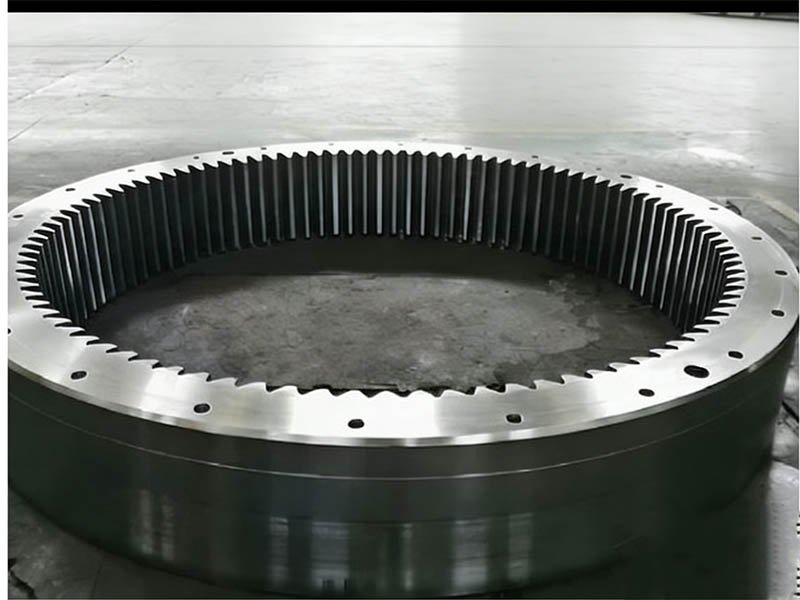

34CrNiMo7-6 Forged Gear Blanks for Wind turbine

Our 34CrNiMo7-6 gear blanks combine advanced metallurgy with precision forging. Designed for critical applications in main gearboxes, yaw systems, and pitch drives, each forging forms the durable foundation for decades of operation. Engineered to support precision machining and heat treatment, our blanks enable final gears to achieve over 25 years of service life in the most extreme onshore and offshore environments.

Description

The wind energy sector demands components of uncompromising integrity. As a trusted manufacturer, we specialize in high-performance gear blankS forgings—the core of reliable wind turbines.

Our 34CrNiMo7-6 gear blanks combine advanced metallurgy with precision forging. Designed for critical applications in main gearboxes, yaw systems, and pitch drives, each forging forms the durable foundation for decades of operation. Engineered to support precision machining and heat treatment, our blanks enable final gears to achieve over 25 years of service life in the most extreme onshore and offshore environments.

Commitment to gear blank material Superiority

We begin with material excellence. Our standard grades—including 34CrNiMo7-6, 18CrNiMo7-6, 20CrMnTi, and 4340—are selected for optimal strength, toughness, and hardenability. We also offer customized material solutions that comply with DIN, EN, ASTM, and GB standards. For critical applications, ultra-purified steel ingots with oxygen ≤15ppm and hydrogen ≤1.5ppm are available to ensure maximum fatigue resistance and structural integrity.

A gear blank manufacturing process for Precision

Our manufacturing process follows a rigorous, controlled sequence to ensure consistent quality. It begins with Material Verification to confirm precise chemical composition. During Preparation & Forging, we apply monitored deformation to optimize grain structure. After Rough Machining, Pre-HT Inspection validates dimensions and surface integrity. The Quenching & Tempering stage is precisely controlled to develop strength and toughness, verified through Post-QT Inspection of mechanical and microstructural properties. The process concludes with Finishing & Final Release, delivering a blank fully prepared for final custom gear machining.

Quality Assured at Every Stage

Our quality assurance is not a final checkpoint but a philosophy integrated throughout production. Our full-process inspection system begins with Raw Material Inspection, utilizing spectrochemical analysis and macrostructure exams. Throughout production, In-Process Monitoring via infrared temperature tracking and online dimensional gauging ensures process stability. Before release, each forging undergoes Final Validation, including sensitive Ultrasonic Testing (capable of detecting flaws as small as Φ1.6mm), 100% surface inspection via Magnetic Particle Testing, complete mechanical property testing, microstructural evaluation, and precise dimensional verification using Coordinate Measuring Machines.

Certified for Global Deployment

Our commitment to quality is validated by internationally recognized certifications, including ISO 9001:2015 for quality management, ISO 14001 for environmental management, and ISO 45001 for occupational health and safety. Our products and processes are developed in strict adherence to leading technical standards such as EN ISO 6336, DIN 3990, IEC 61400, and GB/T 19073.

Powering the Present and Future of Wind Energy

Our seamless rolled gear blank forgings are engineered for diverse applications across the wind energy spectrum. They are integral to Onshore Wind Turbines, supporting the reliable operation of mainstream 2–6 MW platforms. For the more demanding Offshore Wind Turbines, they provide the necessary durability for high-power 6–15 MW models. We also support the longevity of existing infrastructure through Retrofit & Service, supplying high-quality replacement blanks and spare parts. Looking ahead, our technology is ready for Next-Gen Platforms, including innovative floating wind and airborne wind energy systems.

Why Partner with Us?

Choosing our gear blank forgings means selecting a partner dedicated to more than just supply. You gain access to Proven Reliability forged for extended service in extreme climates, ensured by Full Traceability from the melt to your machining line. Our team provides proactive Technical Support and custom engineering advisory, backed by Global Certifications that meet the stringent requirements of the international wind industry. We are not just your supplier; we are your strategic ally in building a more resilient and powerful wind energy future.