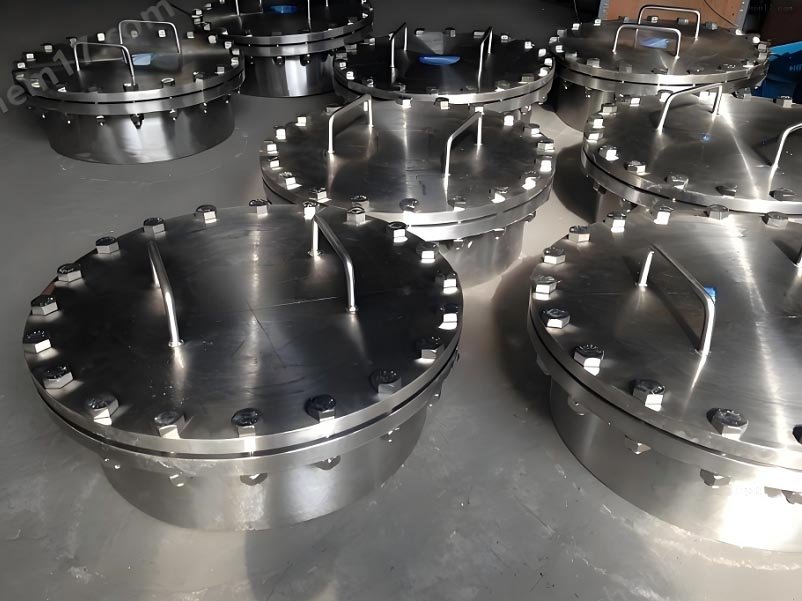

16Mn Manway Nozzle Forgings: High-Integrity Forged Vessel Connections

Pressure vessel manhole forgings act as the core pressure-bearing and connecting interface within the manhole structure. Unlike simple welded pipes, these are forged components created as a unified whole from the nozzle, the shell, and reinforcing metals

Description

The Critical Role of Manway Nozzle Forgings in Pressure Vessels

Pressure vessel manhole forgings act as the core pressure-bearing and connecting interface within the manhole structure. Unlike simple welded pipes, these are forged components created as a unified whole from the nozzle, the shell, and reinforcing metals.

Their core function is engineered for safety: through the continuous metal flow lines formed by the overall forging process, reinforcing materials are precisely concentrated in the high-stress areas of the opening. This significantly enhances structural strength, reduces stress concentration, and strengthens resistance to fatigue and crack propagation. Ultimately, our manway nozzle forgings ensure the long-term sealing safety and structural integrity of the vessel under high pressure, extreme temperatures, or cyclic loads, providing a sturdy support foundation for personnel entry and maintenance.

Material Specifications for Forged Components and Manway Nozzles

The material selection for manway nozzle forgings strictly complies with relevant standards such as GB/T 16508 or ASME codes. We ensure that all forged components undergo appropriate heat treatment and non-destructive testing to meet stringent safety requirements.

The material is determined based on the vessel’s design parameters, working medium, and standard specifications. Common options include:

Carbon Steel: High-quality 16Mn Manway Nozzle Forgings.

Low Alloy Steel: Such as 15CrMo.

Stainless Steel: SUS304, 316L for corrosive environments.

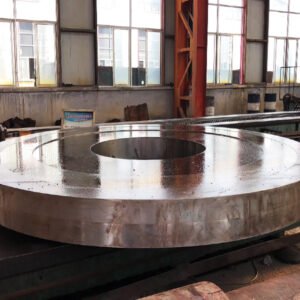

Manufacturing Process of Forged Vessel Connections

Our manufacturing employs a strictly controllable process to ensure the integrity of every manway nozzle: “High-quality steel ingot → Forging → Normalizing/Quenching & Tempering Heat Treatment → Rough Machining → UT/MT Non-destructive Testing → Performance Heat Treatment.”

Quality Assurance for Manway Nozzle Forgings

We have established a comprehensive testing network to ensure foolproof quality for every nozzle manufactured in our facility:

Non-destructive testing (NDT): 100% ultrasonic testing (UT, conforming to JB/T4730.3 Level I or ASME SE-213 standard), magnetic particle testing (MT), or penetrant testing (PT) to accurately detect subtle internal and surface defects in the forged components.

Mechanical performance testing: Samples are taken from the main body or test blocks of each batch for tensile, impact, hardness, and necessary intergranular corrosion tests. The data is authentic and traceable.

Metallographic and chemical analysis: Spectrometers and metallographic microscopes are used to strictly control material composition and microstructure.

Ensuring Sealing Integrity with the Manway Nozzle Gasket

A critical aspect of the manway system is the sealing surface. Our forgings are machined to precise tolerances to ensure a perfect mating surface for the manway nozzle gasket. Whether using spiral wound or ring joint gaskets, our precise facing ensures leak-free performance under pressure.

Typical Application Scenarios for Manway Nozzles

Our high-strength forged vessel connections are widely used in critical industrial fields demanding the highest level of safety:

Petroleum Refining: Hydrogenation reactors, catalytic cracking units, and distillation towers.

Chemical Industry: Ammonia synthesis, urea equipment, and polyethylene reactors.

Nuclear Power: Conventional island pressure vessels requiring nuclear-grade certification.

Clean Energy: Liquefied natural gas (LNG) storage tanks and coal chemical gasifiers.

Offshore Engineering: FPSO topside modules and subsea pipeline terminals.

Engineering Support and Lifecycle Service

We provide comprehensive support throughout the entire project. Our engineering team assists from the initial design stage, offering professional material selection and structural design for your manway nozzle forgings. Relying on a mature supply chain, we ensure timely delivery and provide continuous technical consulting and after-sales support.

FAQ: Why Choose Forged Manway Nozzles Over Castings?

Advantages of Forged Components in High-Stress Environments

Compared with cast or welded parts, manway nozzle forgings formed by free forging and die forging offer significant advantages:

Dense Microstructure: During the forging process, large dendrites and pores are crushed under high pressure, resulting in continuous metal flow lines.

Superior Strength: This leads to excellent strength, toughness, and fatigue life.

Enhanced Safety: The uniform and fine grain structure brings stronger pressure-bearing capacity and stress corrosion resistance.

Reliability: Full traceability eliminates potential risks often associated with welding defects, making forged vessel connections the safer choice.

Partner with a Forging Manufactuer Directly

An extremely straightforward way to guarantee full traceability is to completely eliminate the middleman. When you buy your Manway Nozzle Forgings direct from our factory, you get to control the quality, delivery time, and price. Our prices for forged vessel connections are very competitive, and we do not compromise on the durability which can only be achieved by a real forging. Feel factory-direct quality difference