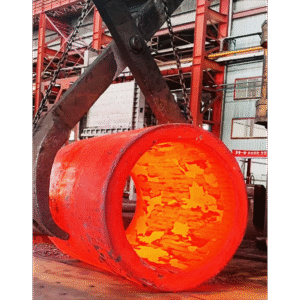

14Cr1Mo Forged Cylinder Shell

system running in the most harsh environments of the petrochemical, power generation, and boiler manufacturing industries. The 14Cr1Mo cylinder shell is a product that perfectly fits such extreme scenarios. It combines the best heat-resistant 14Cr1Mo—a high-quality chromium-molybdenum alloy steel—with the excellent mechanical strength obtained by the forging process in an impeccable way.

Description

Component reliability is the factor that keeps the whole industrial system running in the most harsh environments of the petrochemical, power generation, and boiler manufacturing industries. The 14Cr1Mo cylinder shell is a product that perfectly fits such extreme scenarios. It combines the best heat-resistant 14Cr1Mo—a high-quality chromium-molybdenum alloy steel—with the excellent mechanical strength obtained by the forging process in an impeccable way. Thus, it acts as a guarantee of safe operation for long cycles under conditions of high temperatures and heavy pressures.

The 14Cr1Mo Material Advantage: Why CrMo Steel?

Identifying the right material is the most important step in the production of a high-performance cylinder shell. The material 14Cr1Mo is a carbon-manganese based alloy steel (CrMo) made of the combination of elements molybdenum, chromium, and nickel (14Cr1Mo), which intensively did it for use in elevated temperature and pressure applications.

- Excellent High-Temperature Strength: 14Cr1Mo maintains a strong framework and can carry loads even at temps of nearly 500°C (932°F) and above.

- Superior Creep Resistance: Under all conditions of heat and stress, it slows down plastic deformation or creep, allowing the cylinder to hold its shape.

- Hydrogen Corrosion Resistance: It paves the way for the use of the same structures in extremely hot and high-pressure hydrogen-containing environments in the petrochemical industry.

Superior Structure: The Open Die Forging Process

We produce these cylinder shells by an open die forging method, which is a totally different method from casting or rolling of the plates. The forgingmachine works bypressure and hammering which forces the steel to change its shape internally.

- Refined Grain Structure: The fiber structure in tightly forged woods is much finer than in casting and the material is stronger, since the pores are closed and the material is aligned in the direction of the cylinder.

- Eliminates Defect Risks: A community due to its internal density automatically embraces the complete absence of leakages or weak spots around the welds because of the welding process lesions by the forging process.

- Enhanced Mechanical Properties: When compared with the same material in casting, a forged 14Cr1Mo cylinder shell would have a much higher tensile strength and yield strength thus being more worthy of extreme pressure

Key Applications for 14Cr1Mo Forged Components

Due to the capability of the 14Cr1Mo forged shell to resist both heat and pressure, it is one of the cores of the heavy metal industries various kinds of machines.

- Petrochemical Reactors: The usage is in hydrocracking reactors or any other high-temperature chemical processes.

- Power Generation Components: For instance, steam turbine casings or high-temperature piping systems.

- HydraulicCylinders:Particularly,for heavy-duty hydraulic systems that operate in high-temperature environments.

Custom Forging and Machining Services

We know that the industrial projects you have are different and each has its own unique requirements. To meet your exact specifications, we provide a full range of forging and machining services.

Our workforce is able to deliver a turnkey solution including forging from raw materials and final precision machining according to your drawings. In case you require a rough-forged blank or a fully heat-treated and finished ready-to-install cylinder shell, we guarantee the utmost quality standards and dimensional accuracy.