Custom Forge Services for Heavy Industrial Parts

In heavy industry, standard components are often not enough. Load conditions, dimensional limits and material performance requirements vary from project to project. That is where custom forge manufacturing becomes necessary.

At TIPTOP Heavy Forging, we focus on producing custom forgings for structural and mechanical applications where strength, internal soundness and long-term reliability matter more than appearance or volume output.

This article explains how custom metal forging works, when custom steel forging is the right solution, and what customers should expect from a custom forged parts manufacturer.

Hammer Forging Process: Industrial Equipment, Forging Hammer Types, and Reliable Manufacturing Solutions

The hammer forging process is an impact-based metal forming method widely used in heavy industry. By shaping heated steel through controlled blows, manufacturers can improve internal structure and mechanical strength compared with non-forged alternatives.

Hammer Forgings: Custom Hammer Forged Parts and Industrial Metal Hammer Forging Capabilities

Hammer forgings are widely used in heavy-duty industries where structural strength and material reliability are critical. Compared with casting or simple machining, the hammer forging process reshapes heated metal through controlled impact, improving internal structure and load performance.

Hammer Forge: Power Hammer Forging Technology and Industrial Applications

The hammer forge process shapes heated metal using repeated high-energy impacts delivered by a forging hammer machine. Unlike press forging, which applies continuous pressure, hammer forging relies on dynamic impact force to deform the material.

In power hammer forging, the ram is accelerated mechanically, pneumatically, or hydraulically before striking the workpiece. The high strain rate improves grain flow and refines microstructure, especially in alloy steel components.

Steam Turbine Rotor Forgings for Power Generation and Industrial Turbines

Steam turbine rotor forgings are critical components used in power generation and industrial steam turbine systems. The rotor operates under high temperature, high pressure, and continuous rotational load, making forging quality and internal material integrity essential to long-term turbine reliability.

TIP TOP Forging specializes in manufacturing steam turbine rotor forgings and steam turbine rotor shaft forging products for turbine manufacturers, service companies, and power plant projects. We focus on supplying forged rotor bodies and shafts rather than complete turbine assemblies.

Steam Turbine Rotor Forging Manufacturer & Manufacturing Process Overview

The steam turbine rotor is a very significant rotating part inside the steam turbine and it is the one that makes the transformation of thermal energy (from steam) into mechanical energy possible. It is a part under extreme working conditions such as high temperature, high pressure, as well as continuous rotational stress. Hence, the forging of the rotor and the material used for it should be of very high quality and free of any defect for the safety and efficiency of the turbine.

Forged Rings: Manufacturing Process and Industrial Applications

Forged rings are seamless circular metal components produced through controlled forging processes to achieve high structural integrity and reliable mechanical performance. Compared with cast or welded rings, forged rings offer superior grain flow continuity, higher load-bearing capacity, and improved fatigue resistance. These advantages make forged rings essential for demanding industrial applications where strength, dimensional stability, and long service life are required.

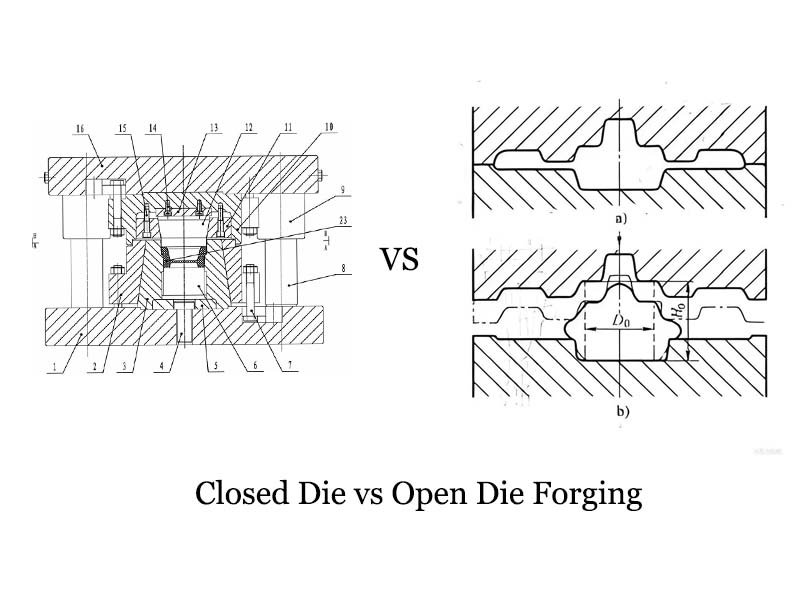

Closed Die vs Open Die Forging: How to Choose the Right Forging Method

In industrial manufacturing, the comparison between closed die vs open die forging is rarely theoretical. It usually starts with a real question: Can this part meet performance and tolerance requirements without unnecessary cost or risk? Understanding how these two forging methods behave in actual production environments is essential for making the right technical and commercial decision.

Closed Die Forging: Process, Advantages, Presses and Applications

Closeddie forging—also known as impression die forging—is a highly productive metal shaping process in which heated metal is worked inside the closed dies to manufacture parts of a definite shape and having good mechanical properties. By forging metal inside a pre-planned die cavity, closed die forging provides a means for producing parts near-net or net-shape with higher strength, better repeatability, and greater dimensional accuracy. As such, the process is a good fit for parts that must perform reliably and be safe.

Forging Manufacturing Process for Heavy-Duty Industrial Components

In heavy industrial fields, the forging manufacturing process is not chosen for convenience. It is selected because the component must survive real working conditions—continuous load, repeated stress, and long service cycles. Whether the part is used in oil and gas equipment, mining machinery, or power transmission systems, forging remains one of the most reliable manufacturing routes.