Mining Forging Solutions for Heavy-Duty Equipment and Harsh Environments

Mining operations rely on durable components that can withstand impact, abrasion, variable loads, and long-term exposure to harsh working conditions. This is why forging plays a critical role in producing the structural and power-transmission parts used across drilling, hauling, crushing, and mineral-processing equipment. Compared with cast or fabricated pieces, forged metals offer higher density, refined grain structure, and superior mechanical reliability—making them the preferred choice for heavy-duty mining applications.

At TIP TOP, we supply high-quality forged components not only for the oil and gas industry, but also for mining customers worldwide who depend on steady delivery, consistent quality, and tailored metal forging solutions to keep their operations running smoothly.

Why Mining Forging Is Essential for Modern Mining Equipment

Mining equipment operates under heavy loads, constant vibration and abrasive contact with ore. Mining forgings offer several advantages that directly address these challenges:

- Superior tensile and impact strength

- Uniform grain flow aligned with the part’s stress path

- Resistance to cracking and deformation

- Extended fatigue life under cyclic loading

- Lower failure rate compared with cast parts

These properties make forged metals the preferred choice for OEMs, maintenance contractors and mining equipment fabrication companies worldwide.

Common Applications of Mining Forged Parts

Different mining operations require a wide range of mining forged parts, covering both underground and open-pit environments. Typical forged components include:

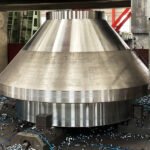

- Crusher shafts, cone crusher main shafts and hammer pins

- Drill rods, drill subs, couplings and rotary drilling components

- Track pads, drive sprockets, rollers and bushings for heavy machinery

- Gear blanks, ring gears and transmission shafts

- Bearing housings, hubs and connector flanges

- Hydraulic cylinder components and actuator parts

These parts must sustain abrasion from rock, high torque levels, and sudden impact — requirements that are difficult to meet without forging.

Materials Used in Mining Forging and Their Performance Benefits

Mining equipment demands materials that balance strength, toughness and wear resistance. TIP TOP provides forging solutions using:

- Alloy steels (most common for mining equipment due to high strength and toughness)

- Carbon steels for general mechanical applications

- Stainless steels for corrosion-exposed components

- Tool steels for high-wear contact surfaces

- Nickel and special alloys for extreme or high-temperature applications

These materials form the core of the forged metals used across mining machinery manufacturers. As an experienced metal forger, TIP TOP ensures proper heat treatment, controlled forging reduction and mechanical consistency.

Mining Forging Processes Used to Produce High-Strength Parts

Different forging processes support different mining applications. TIP TOP offers multiple production routes depending on size, geometry and performance requirements:

Open-die forging for large mining forging components

Ideal for shafts, rings, blocks and heavy machine parts requiring deep penetration and high toughness.

Closed-die forging for near-net mining forged parts

Used for components requiring accuracy, such as gears, couplings, drill connectors and specialty tooling.

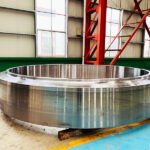

Ring-rolling for high-strength rings and gear blanks

Ensures uniform grain flow and excellent fatigue resistance in transmission components.

Forging combined with machining for equipment-ready parts

Allows customers to receive semi-finished or finished forged components ready for assembly.

These methods ensure the structural strength required for forge mining environments, where mechanical failure can lead to high downtime costs.

Advantages of Forged Metals Over Cast or Fabricated Alternatives

Mining operators prefer forged parts because of the clear performance benefits:

- No internal porosity or shrinkage defects

- Better shock and impact resistance

- Longer service life in abrasive conditions

- Predictable mechanical properties after heat treatment

- Higher reliability in safety-critical equipment

This is why many global OEMs rely on mining forging suppliers instead of cast or welded component manufacturers.

Industry Trends in the Mining Forging Market

The mining sector continues to increase its demand for mining forgings due to:

Rising production of iron ore, copper, nickel and rare earth minerals

Growth of large-scale crushing and conveying systems

Higher performance requirements for underground machinery

Longer equipment life targets from OEMs

Global need for stable, diversified forging supply chains

In parallel, maintenance and repair operations (MRO) seek durable forged components to reduce operational downtime.

TIP TOP Capabilities as a Reliable Mining Forging Supplier

TIP TOP provides forged metals and customized forging services for mining customers worldwide. Our capabilities include:

- Forging of alloy steels, carbon steel, stainless steel and high-strength special alloys

- Production of shafts, rings, cylinders, couplings and precision forged components

- Engineering support for mining equipment fabrication and redesign

- Heat-treatment control for high toughness and wear resistance

- Ultrasonic testing, mechanical testing and dimensional inspection

- Stable supply capacity for long-term mining procurement projects

As one of the dependable alloy steel forging manufacturers, TIP TOP ensures each forged part meets the operational demands of modern mining operations.

Applications We Support in the Mining Industry

TIP TOP manufactured forged parts are widely used in:

- Surface mining machines (shovels, excavators, loaders)

- Underground drilling equipment

- Ore crushing, milling, and screening systems

- Bulk material handling and conveyor systems

- Mineral processing and pump systems

- Gearbox and power-transmission equipment

We work closely with engineering teams and mining operational managers to deliver forgings that improve durability, safety and operational efficiency.

Conclusion

Mining environments place extreme demands on mechanical components, making forging one of the most reliable manufacturing processes for the industry. With strong technical capacity and stable supply, TIP TOP delivers forged components that meet the heavy-duty requirements of global mining operations. Whether you need large open-die shafts, precision closed-die parts, or custom forged metals for new equipment development — TIP TOP is ready to support your project