Nuclear Forgings Manufacturer for Reliable Power Generation

Nuclear power plants require components that can withstand high pressure, extreme temperature, and long-term radiation exposure. These challenges make nuclear forgings a preferred solution for pressure vessels, steam generators, reactor internals, turbine shafts, and other safety-critical parts.

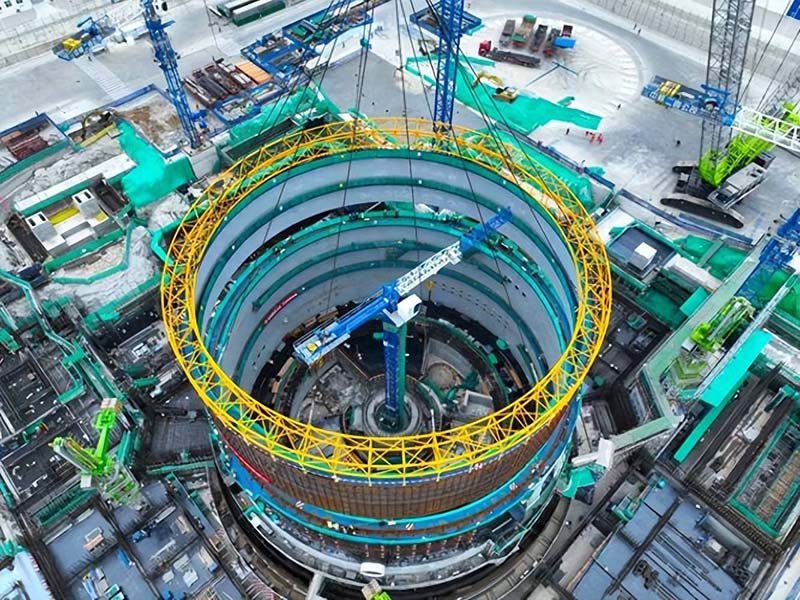

Nuclear Forgings for High-Safety Nuclear Power Applications

Nuclear forgings are critical components used in nuclear power equipment such as the Nuclear Reactor Vessel, Nuclear Reactor Steam Generator, and Nuclear Pressure Vessel. These parts operate in extreme pressure, temperature, and radiation environments, so the forgings must meet the highest standards of strength, toughness, and reliability.

Aerospace Forging Market Solutions for Aircraft Components

The aerospace forging market is thriving as one of the main requirements is the aircraft manufacturers desire for lighter, safer and more durable components. Compared to cast or fabricated parts, aerospace forgings offer better grain flow alignment, structural integrity and resistance to fatigue over time – feature set necessary for example aircraft engines, landing gear and structural frameworks.

High-Performance Forged Components for Heavy-Duty Mining Operations

Mining operations depend on extreme durability, stable mechanical performance, and long service life from every component on-site. This is exactly why forge mining technologies — including open-die forging, closed-die forging, and ring rolling — remain the backbone of the global mining industry. From crushers and excavators to drilling systems and ore-handling equipment, forged parts offer unmatched reliability in high-impact and high-pressure environments.

Mining Forging Solutions

Mining operations rely on durable components that can withstand impact, abrasion, variable loading and long-term exposure to extreme working conditions. For this reason, mining forging technology plays a central role in the production of structural and power-transmission parts used in drilling, hauling, crushing and mineral processing equipment. Forged metals have higher density, refined grain structure and better mechanical integrity compared with cast or fabricated alternatives, making them a critical choice for demanding mining applications.

Aerospace Forgings

The aerospace industry relies heavily on forged metal parts because aircraft components operate under high load, temperature changes, vibration and long service cycles. Compared with cast or welded structures, aerospace forgings offer more reliable grain flow, higher fatigue strength and better metallurgical integrity. These advantages make forging the preferred process for engine, landing gear, structural and transmission parts across both commercial and military platforms.

Large Forging for Power Generation

In The Power Generation Industry, Every Component Must Withstand Extreme Loads, Harsh Environments, And Decades Of Continuous Operation. This Is Why Large Forging For Power Generation Is Preferred Over Casting Or Welding For Critical Parts.

Hydropower Forging

Hydropower Remains One Of The Most Stable And Efficient Renewable Energy Sources, Powering Industries And Communities Worldwide. At The Heart Of Every Hydropower Plant Lies A Series Of Critical Forged Components, Collectively Known As Hydropower Forging. These Parts Must Withstand Immense Water Pressure, High Torque, And Decades Of Continuous Operation Without Failure.