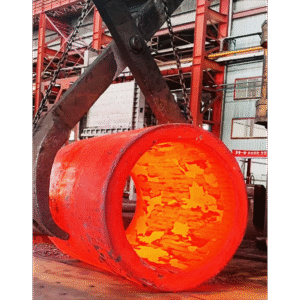

Inconel 625 Pressure Vessel Shell Forging

The pressure vessel shell is the primary load-bearing component of a pressure vessel, responsible for withstanding internal pressure, containing process media, and maintaining the overall structural integrity of the equipment. In pressure vessel engineering, the shell refers to the cylindrical or spherical body section that operates under internal pressure and temperature, forming the core of the vessel structure.

Description

Product Overview – Pressure Vessel Shell Forging for Critical Applications

The pressure vessel shell is the primary load-bearing component of a pressure vessel, responsible for withstanding internal pressure, containing process media, and maintaining the overall structural integrity of the equipment. In pressure vessel engineering, the shell refers to the cylindrical or spherical body section that operates under internal pressure and temperature, forming the core of the vessel structure.

In a complete pressure vessel assembly, the pressure vessel shell works together with heads, flanges, nozzles, and manways, which are joined through welding or bolted connections. The mechanical reliability of the shell directly determines the safety margin, service life, and compliance of the entire vessel. For demanding environments, forged and rolled steel shells for pressure vessels provide superior integrity compared with welded plate constructions.

Pressure Vessel Shell Material Selection

The choice of pressure vessel shell material depends on operating pressure, temperature, corrosion environment, and design life. We supply shell forgings manufactured from a wide range of qualified materials sourced from leading domestic mills or international producers.

Carbon steel series

Q245R, Q345R, 16Mn (forged)

Low-alloy and Cr-Mo steel series

15CrMoR, 12Cr2Mo1R (2.25Cr–1Mo–0.25V), SA-387 Gr.11 / Gr.22

Stainless steel and duplex steel series

304, 304L, 316, 316L, S32168, S31803 (duplex)

Special materials for extreme conditions

Nickel-based alloys (Inconel 600 / Inconel 625, Monel 400)

Low-temperature steels (09MnNiDR)

Among these, Inconel 625 pressure vessel shell forgings are particularly suitable for high-temperature, high-pressure, and strongly corrosive environments where conventional steel shells reach their performance limits.

Forging Technology for Pressure Vessel Shells

Our pressure vessel shells are produced using heavy-duty hydraulic presses with capacities exceeding 10,000 tons. Free forging is combined with precision forging and die forging techniques to manufacture thick-wall and large-diameter shells.

Through controlled upsetting, drawing, punching, and mandrel reaming processes, the original cast structure is fully broken down, internal porosity is compacted, and a dense, continuous fiber flow is formed. This forging process significantly improves isotropic mechanical properties compared with plate-rolled shells.

For heat treatment, we are equipped with large computer-controlled car-bottom furnaces. Processes such as normalizing and tempering (N&T), quenching and tempering (Q&T), and solution treatment are applied according to pressure vessel shell design requirements. These processes ensure controlled grain size, stable mechanical properties, and effective residual stress elimination.

Quality Assurance of Pressure Vessel Shell Forgings

We persistently adhere to the premier quality and performance standards during the entire manufacturing process of our pressure vessel shell forgings.

These materials are tested for compatibility with the mechanical and chemical requirements with the help of standards and specifications, i.e. ASME SA-266, SA-508, GB/T 12361.

High yield and tensile strength contribute to great pressure-bearing performance and enhanced long-term safety of the operational process.

Low-temperature toughness is meticulously monitored; they kept impact resistance intact at –20°C, –46°C, and even at much lower temperatures, thus mitigating the danger of brittle fracture.

The shells’ outstanding resistance to fatigue and creep allows them to withstand the stress caused by cyclic loading, the high temperature, and high pressure, which are especially challenging conditions for hydrogenation and synthesis reactors.

100% ultrasonic testing (UT) as per JB/T 4730 and ASME SA-388

Complete surface magnetic particle or penetrant testing for surface or subsurface defects

At your option, we can also provide inspection and certification by an international third-party organization to make us a partner you can trust even in the most critical projects.

Whether our pressure vessel shell accessories are serving the oil & gas, petrochemicals, nuclear or any other industry, our accumulated experience in the manufacture of such essential components is sure to meet the demands of the very diverse applications, whose main characteristics can be summarized as follows:

Oil refining and petrochemical industry: hydrogenation reactors, Fischer–Tropsch synthesis reactors, high-temperature high-pressure separators

Nuclear power industry: reactor pressure vessels (RPV), pressurizers, steam generators

Coal chemical industry: gasifiers, methanol synthesis towers, shift converters

Clean energy and hydrogen systems: high-pressure hydrogen storage vessels, CO₂ storage tanks, nuclear-assisted hydrogen production equipment

Marine and offshore engineering: subsea manifolds and underwater pressure vessels

The use of Inconel 625 pressure vessel shell forgings in such extreme service conditions ensures a high level of resistance to various corrosive agents, structural reliability, and a long service life.