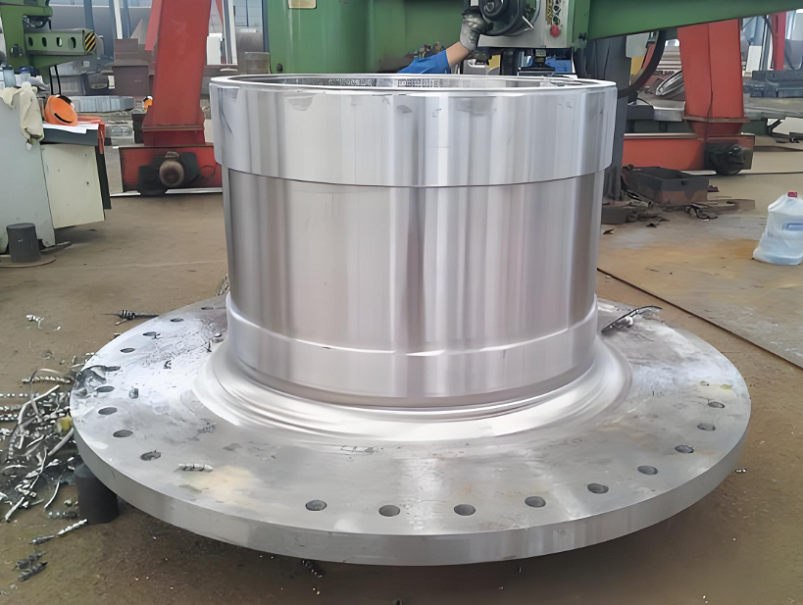

42CrMo4 Mill Shaft for Ball Mill

A mill shaft refers to a shaft with a hollow structure, which is one of the important components of a ball mill. The main function of the ball mill hollow shaft is to transmit the rotational speed and torque driven by the motor to the grinding media and materials, thereby achieving high-speed rotation and grinding of the grinding media and materials.

Description

Product Introduction of Ball Mill Hollow Shaft Forging

A mill shaft refers to a shaft with a hollow structure, which is one of the important components of a ball mill. The main function of the ball mill hollow shaft is to transmit the rotational speed and torque driven by the motor to the grinding media and materials, thereby achieving high-speed rotation and grinding of the grinding media and materials.

Materials for 42CrMo4 Ball Mill Shaft Forgings

The selection of raw materials significantly impacts the forging quality of the hollow shaft. High-quality steel is a common raw material for hollow shaft forging. Our mill shafts generally choose high-quality carbon structural steel or alloy steel, mainly including materials such as 42CrMo4, AISI 4140, 45#, 50Mn, and 40Cr.

Forging Process of Hollow Mill Shaft for Ball Mill

Heating temperature can improve the forging performance of the material. The selection of forging equipment depends on the size and precision of the shaft; hydraulic presses are commonly used for hollow shaft forging, and air hammers can also be used for smaller shafts.

The forging ratio is an important indicator; a sufficient forging ratio can make the structure denser. Upsetting is used to increase the cross-sectional area of the material, and punching is a key operation to form the hollow part, requiring precise positioning of the punch. Expanding is used to enlarge the inner diameter, and various methods need to be selected appropriately.

During the forging process, the deformation amount needs to be controlled; excessive deformation may lead to cracks, while too fast a forging speed can easily cause defects. Attention should be paid to stress distribution, as uneven stress distribution may cause abnormal deformation.

The cooling method has a significant impact on performance; isothermal cooling helps control structural transformation. Normalizing can improve overall mechanical properties, and tempering can eliminate residual stress.

Quality Control and Inspection of Ball Mill Hollow Shaft Forgings

The surface quality should be free of cracks and obvious defects, and the dimensional and shape accuracy must meet design requirements. Non-destructive testing can detect internal defects, hardness testing evaluates the heat treatment effect, and metallographic analysis is used to observe the microstructure.

Advanced simulation technology helps optimize the forging process, and continuous process improvement ensures that hollow mill shaft forgings can meet various application needs in ball mill equipment.