SAE4330V Fluid End

In the high-stakes world of hydraulic fracturing, downtime is not an option. The SAE4330V Fluid End acts as the heart of the fracturing pump, engineered to survive where others fail. As a premium modification of standard alloy steels, SAE4330V (Cr-Ni-Mo-V) has established itself as the global gold standard for manufacturing high-pressure fracturing pump fluid ends and valve blocks.

Description

In the high-stakes world of hydraulic fracturing, downtime is not an option. The SAE4330V Fluid End acts as the heart of the fracturing pump, engineered to survive where others fail. As a premium modification of standard alloy steels, SAE4330V (Cr-Ni-Mo-V) has established itself as the global gold standard for manufacturing high-pressure fracturing pump fluid ends and valve blocks.

The SAE 4330V Advantage: Built for Fracture Toughness

Hydraulic fracturing operations subject equipment to brutal conditions: acidizing fluids, high sand-ratio slurries, and extreme cyclic pressures. Standard steels often succumb to fatigue cracking under these loads.

SAE4330V is distinguished by the addition of Vanadium, which acts as a grain refiner, and the use of the Electroslag Remelting (ESR) process. This combination delivers:

Superior Fracture Toughness: It resists the initiation and propagation of cracks better than 4340 or standard 4140 grades.

High Hardenability: Ensures uniform mechanical properties throughout the thick cross-sections of massive fluid end blocks.

Super-Clean Steel for Maximum Fatigue Life

The longevity of a fluid end is directly tied to the purity of the steel. Inclusions act as stress risers that lead to catastrophic failure. We adhere to ultra-strict control over gases and harmful elements to ensure a homogeneous microstructure:

Total Oxygen (T.O): ≤ 0.0015% (Minimizes non-metallic oxide inclusions).

Phosphorus (P): ≤ 0.008% (Prevents cold brittleness).

Sulfur (S): ≤ 0.005% (Improves impact toughness).

Mechanical Performance Specifications

Our forged SAE4330V blocks undergo precise Quenching and Tempering (Q&T) to achieve an exceptional balance of high strength and ductility, capable of withstanding massive alternating stresses.

| Property | Value |

| Tensile Strength | ≥ 1600 MPa |

| Yield Strength | ≥ 1300 MPa |

| Impact Energy (CVN) | ≥ 55 J (-40°C or Ambient) |

| Hardness | 38 – 43 HRC (Customizable) |

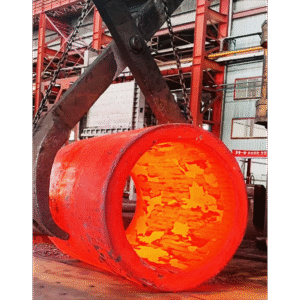

Forging and Application

We utilize multi-directional forging techniques to produce SAE4330V fluid end blanks. This process eliminates internal porosity and aligns the grain flow with the stress contours of the part, providing superior strength compared to castings or simple billets.

Applications:

Frac Pumps: Quintuplex and Triplex fluid ends for 2500HP, 3000HP, and 5000HP fracturing units.

Replacement Blocks: Compatible with major pump designs used in shale gas and tight oil exploration.

High-Pressure Service: Designed for operational pressures exceeding 15,000 PSI under heavy shock loads.

Exceeding API Standards with Every Forge Your high-pressure pumps require more than just steel; they require material science. With total oxygen content ≤0.0015% and optimized grain flow, our SAE4330V forgings are built to withstand the harshest cyclic loading. Validate our quality with your own eyes—third-party inspection (TPI) is always welcome. Let’s discuss your technical specifications. [Inquire Now]