In the high-stakes world of heavy industry, component failure is not an option. As a premier China large forging manufacturer, TIP TOP Forging understands that the integrity of your machinery relies heavily on the quality of its core components. We specialize in the production of high-performance large forgings, combining decades of metallurgical expertise with state-of-the-art large forge capabilities. Whether you require large industrial forged rings or complex customized large forgings, our facility is engineered to deliver solutions that meet the most rigorous international standards.

Advanced Open Die Processes for Superior Large Forgings

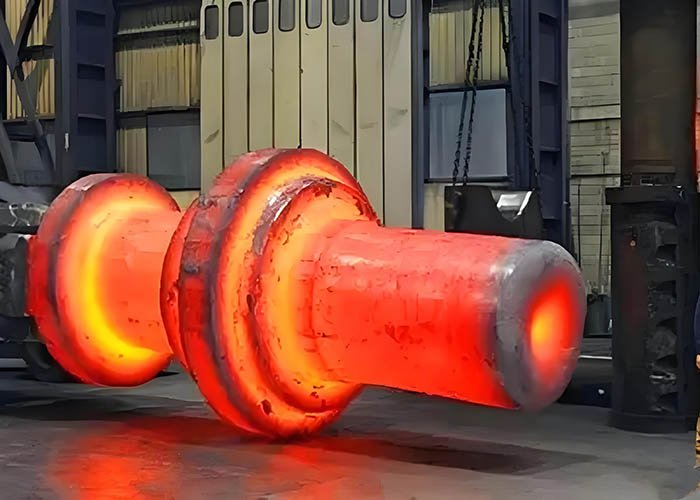

Creating large steel forgings that can withstand extreme mechanical stress requires more than just heavy machinery; it requires a deep understanding of thermal dynamics and metal deformation. Unlike casting, the production of a large forging via the open-die process refines the internal grain structure of the metal.

At TIP TOP Forging, we utilize high-tonnage hydraulic presses to work the material, ensuring continuous grain flow and eliminating internal porosity. This technical precision results in components with superior fatigue resistance and impact strength. Our engineering team meticulously controls the reduction ratio, ensuring that every large hollow tube forged part or solid shaft we produce maintains consistent mechanical properties from the surface to the core. This level of process control is what sets us apart from other large forging companies.

Diverse Product Portfolio of Customized Large Forgings

As a versatile China large forging supplier, we cater to a wide array of specifications. Our manufacturing capacity allows us to handle various grades of carbon steel, alloy steel, and stainless steel.

Large Diameter Forged Rings: Utilizing seamless ring rolling technology, we produce large diameter forged rings and large industrial forged rings essential for wind turbine flanges, slewing bearings, and pressure vessel connections.

Heavy Shafts and Hollows: We are experts in manufacturing large hollow tube forged part components used in high-pressure fluid systems, as well as solid shafts for heavy machinery.

Material Expertise (e.g., 4140): We have extensive experience with specific high-strength alloys. Our 4140 large forgings are particularly sought after for their excellent balance of ductility and strength, making them ideal for automotive and aerospace tooling.

Custom Solutions: We provide customized large forgings tailored to your exact blueprints, including stepped shafts, blocks, and discs.

Critical Applications Demanding Heavy-Duty Large Forgings

Our large forgings supply chain supports critical infrastructure sectors where durability is paramount. We understand the specific nuances of each industry:

Power Generation: We are a trusted source of large forging for power generation. Our rotors, turbine shafts, and generator spindles are manufactured to operate reliably in high-temperature and high-speed environments.

Mining and Excavation: The large mining forging components we produce, such as crusher shafts and gears, are heat-treated to resist the abrasive and high-impact conditions typical of mining sites.

Oil & Gas: We supply large forgings for subsea and surface applications, ensuring compliance with strict NDT (Non-Destructive Testing) requirements.

Why Partner with a Leading China Large Forgings Factory?

Selecting the right partner among global large forging companies is a strategic decision. TIP TOP Forging operates not just as a factory, but as a technical partner. Here is how we ensure Trustworthiness and quality as a top-tier China large forging factory:

Rigorous Quality Control: Every large forging undergoes comprehensive testing, including Ultrasonic Testing (UT), Magnetic Particle Inspection (MT), and chemical analysis. We ensure every item listed as China large forgings for sale meets ASTM, ISO, and DIN standards.

Integrated Heat Treatment: We control the mechanical properties of our large steel forgings through precise normalizing, quenching, and tempering processes within our facility.

Full Supply Chain Management: From sourcing raw ingots to final machining, we act as a comprehensive China large forging manufacturer, reducing lead times and minimizing risk for our clients.

Get Competitive Large Forgings Quotes and Reliable Supply

If you are looking for high-quality China large forgings for sale, TIP TOP Forging offers the perfect blend of technical excellence and cost-efficiency. We understand that procurement managers need more than just a product; they need a reliable logistics partner.

We provide detailed, transparent large forgings quotes that factor in material costs, machining requirements, and shipping logistics. Our global large forgings supply network ensures that whether you are in Europe, the Americas, or Asia, your components arrive on time and ready for installation.

Ready to upgrade your supply chain? Contact TIP TOP Forging today to discuss your specifications. Let us show you why we are the preferred China large forging supplier for heavy industry leaders worldwide.

Contact TIP TOP Forging: For technical inquiries or to request large forgings quotes, please visit our contact page. Trust the experts in large forging technology to support your next major project.