Description

General Introduction to Steam Turbine Rotor Forging

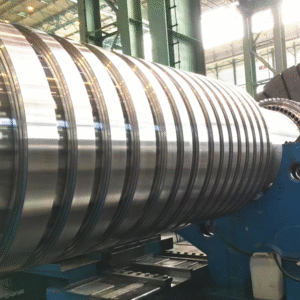

The steam turbine rotor is the core rotating component in a steam turbine unit and plays a decisive role in power output, efficiency, and operational safety. As the main rotor in a steam turbine, it operates under continuous high-temperature, high-pressure steam conditions while rotating at high speed.

As the most important component of the steam turbine rotor assembly, the quality of the forging has a significant impact on the control of the vibrations, the fatigue life, and the long-term trustworthiness. A correctly engineered and manufactured rotor usually has a design life of more than 30 years, thus, the choice of the material and the quality of the forging are of great importance.

Steam Turbine Rotor Material Selection

Material of Steam Turbine Rotor: 30Cr2Ni4MoV Alloy Steel

This steam turbine rotor forging is made from 30Cr2Ni4MoV and 25Cr2NiMo1V high-performance alloy steel, which are generally considered the most suitable materials for a steam turbine rotor of a medium- and large-capacity turbine unit.

These materials offer:

Excellent creep resistance under long-term high-temperature service

High fracture toughness for enhanced operational safety

Outstanding fatigue strength suitable for continuous rotation

Stable metallurgical structure after heat treatment

The optimized material of steam turbine rotor ensures consistent performance in demanding thermal and mechanical conditions.

Steam Turbine Rotor Design and Structural Features

Steam Turbine Rotor Design for Long-Term Stability

The steam turbine rotor design focuses on stress distribution, thermal balance, and rotational stability. Key design considerations include rotor diameter, shaft length, slot geometry, and ventilation structure, all of which directly influence the performance of the steam turbine rotor parts during operation.

Through precise design control, the rotor integrates seamlessly into the complete steam turbine rotor assembly, ensuring compatibility with various turbine and generator configurations.

Manufacturing of Steam Turbine Rotor

Manufacturing Process of Steam Turbine Rotor Forging

We adopt a fully integrated manufacturing process of steam turbine rotor, covering every critical stage from raw material selection to final machining:

Controlled open-die forging to refine grain structure

Precision heat treatment to achieve uniform mechanical properties

Final mechanical machining to ensure dimensional accuracy and balance

Each step in the manufacturing of steam turbine rotor is strictly controlled to meet metallurgical standards and performance requirements for long-term turbine operation.

Applications of Steam Turbine Rotor

Applications of Steam Turbine Rotor in Power Generation

This steam turbine rotor forging is widely used in:

Thermal power plants

Industrial cogeneration units

Steam turbine generator systems

Medium- and large-scale power generation projects

These applications of steam turbine rotor demand high reliability, fatigue resistance, and stable performance over decades of continuous service.

FAQ About Steam Turbine Rotor Forging

Q1: How does the steam turbine rotor design ensure compatibility with different generator types?

A: We offer fully customized steam turbine rotor design services to ensure compatibility within the complete steam turbine rotor assembly. Key parameters such as rotor diameter, length, slot type, and ventilation structure can be adjusted according to generator models, power ranges, and interface standards provided by customers.

Q2: Is special protection available for extreme operating conditions?

A: Yes. Optional enhancement solutions are available for demanding environments:

Surface protection: Anti-corrosion coatings such as phosphating for marine or high-humidity conditions

Fatigue strengthening: Optimized transition radii at rotor ends and slots to reduce stress concentration in frequent start-stop operations

Insulation upgrades: VPI (Vacuum Pressure Impregnation) processes to improve winding insulation and adapt to voltage fluctuations

Q3: Can you provide reference data from previous steam turbine rotor projects?

A: Yes. Performance data and application references for similar steam turbine rotor projects can be provided after signing a confidentiality agreement.