Open Die Forging Definition for Large Forgings

The open die forging process wherein large forgings are being manufactured hostess a manner where huge steel chunks or chunks are being pressed between flat or simple dies without encasing the material fully. This open configuration allows large sections to be deformed in a controlled manner and thereby making open die forging the most feasible method for producing oversized and heavy-duty forged components.

Open die forging of large forgings results in a uniform grain flow and internal density throughout the cross-section, which is the main requirement for the components bearing extreme loads and a long service life.

The Open Die Forging Process for Large-Scale Components

A warm open die process of large components begins by bringing the large ingots to the forging temperature level and after it with a sequence of progressive deformation by using the hydraulic presses with the capacity of high tonnages. The geometry of the material is refined gradually through the repetitions of the operations such as compressions, drawing, upsetting, and shaping.

This method proves to be highly effective for large forgings where closed die tooling is not possible due to various reasons such as size limitations, tooling cost or unique customer requests.

Advantages of Open Die Forging in Large Forging Production

The advantages of open die forging become most evident in the production of large forged parts. The process significantly improves internal soundness, eliminates centerline defects, and enhances directional grain structure across thick sections.

For large forgings, open die forging offers superior fatigue resistance, impact strength, and load-bearing capacity compared with casting or fabrication. It also allows flexible dimensional control and lower tooling investment for low-volume, high-value components.

Application of Open Die Forging for Large Industrial Forgings

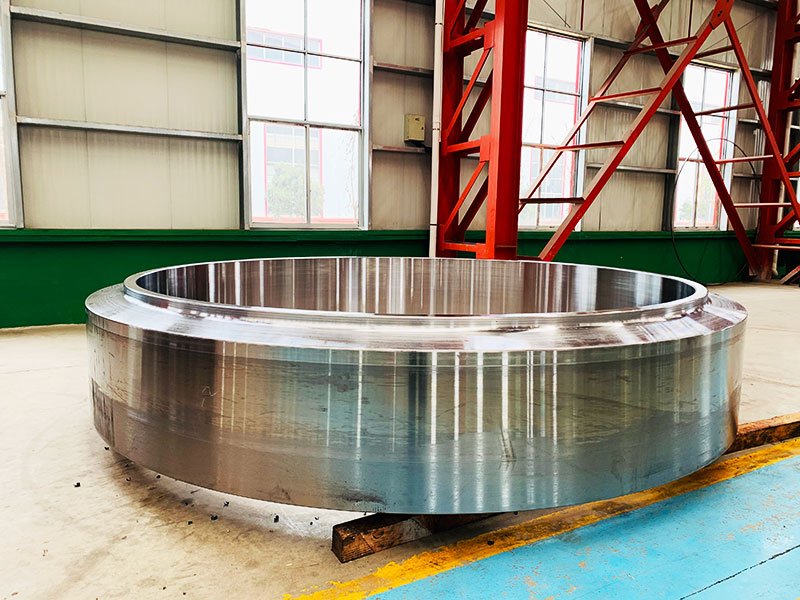

The application of open die forging is primarily concentrated in large industrial forgings where structural reliability is critical. Typical applications include large shafts, thick-walled cylinders, heavy blocks, forged rings, and pressure-containing components.

These large open die forgings are commonly used as core structural elements that require extensive machining after forging to achieve final tolerances and surface finishes.

Open Die Forging Products for Large and Heavy Components

Open die forging products are mainly giant-scale semi-finished forgings such as solid shafts, stepped shafts, hollow cylinders, forged discs, and thick rings. These major forgings are the basis for the significant mechanical and pressure equipment.

Open die forging is the process that is able to provide high accuracy in deformation ratios and thus is appropriate for the production of heavy forgings with consistent mechanical performance and internal quality.

Explanation: Open Die Forging Vs. Closed Die Forging for Large Parts

The open die forging and closed die forging difference is quite apparent when dealing with manufacturing large components. Open die forging can handle almost any amount of parts, while closed die forging has restrictions due to the dimensions of the die and the press capacity.

With open and closed die forging, it’s impossible to switch open die forging for closed die forging and vice versa as each type has its specific application areas. Open die forging is an affordable and feasible method for exceedingly large components, while closed die forging is well suited for small volume and small parts.

Contrast: Open Die Forging Vs. Closed Die Forging in Large Forging Projects

When comparing open die forging and closed die forging technology while dealing with large-scale projects, it can be seen that open die forging has the advantage of more design iteration solutions, lower cost of tools and better internal quality. On the other hand, closed die forging technology is more suitable for projects with defined surfaces but it is unfeasible for large cross-sections.

So open die forging remains the most preferred choice of forging for large custom-made components.

Why Open Die Forging Is Preferred for Large Forged Structures

Open die forging is the most commonly used technique for fabricating large-scale forged structures due to the possibilities it opens in creating deformation over the thickness of the material and controlling the direction of the grain flow. This will definitely result in large sections of the forged part that have a higher level of structural integrity and hence can be relied on to perform under heavy loads in a predictable manner.

In applications where safety, durability, and long-term reliability are priorities, open die forging is the solution that guarantees the desired success in production.

Introduction: Open Die Forging for Large Forgings in TIP TOP

There are a lot of open die forging capabilities in the TIP TOP and they focus on activities targeted at the heavy and extra heavy of forged components. Here, we see that the large ingots go through the high-capacity forging presses, supported with controlled heat treatment and precision machining.

Our large open die forging products are heavy shafts, forged rings, large blocks, hollow forgings, and custom-shaped components manufactured according to customer drawings. The main focus of TIP TOP is the dimensional stability of the parts, the internal quality of the forging, and full material traceability, all of which is ensured in every large forging.

Quality Control for Large Open Die Forgings

Quality control is certainly a huge requirement for such large-sized open die forgings as far as their size and working conditions are concerned. The TIP TOP company uses ultrasonic testing, mechanical property verification, chemical analysis, and dimensional inspection so that every product is the same high level.

All these checking methods guarantee the conformity of the products with relevant standards and customer performance requirements.

Closing: Open Die Forging in Large Forgings as the Main Technology

The best and the most efficient die forging for large well-forged components process is still the open die forging process. Large sections of high internal quality can be produced only by this technique and this is the driving force of its irreplaceability in the industrial applications.

The choice of a qualified, experienced large open die forging manufacturer such as TIP TOP will help customers in securing a number of high-performance forged components which are capable of being used in even the most demanding service conditions.