ASTM A182 F55 Duplex Stainless Steel Flange

The ASTM A182 F55 duplex stainless steel flange is best described as a pipeline connection component made by a forging method. It is the product of the super duplex stainless steel UNS S32760-based material fabricated as per the standard specification ASTM A182/A182M.A forged A182 F55 flange has a refined grain structure, stable mechanical properties, and superior performance as a result of the forging process it is compared with cast alternatives; thus, it is a perfect match for industrial systems of the kind that are piping and that are subjected to heavy work.

Description

Product Overview of A182 F55 Duplex Stainless Steel Flange

The ASTM A182 F55 duplex stainless steel flange is best described as a pipeline connection component made by a forging method. It is the product of the super duplex stainless steel UNS S32760-based material fabricated as per the standard specification ASTM A182/A182M.

The presented grade has been explicitly outlined to be utilized in high-pressure and highly corrosive environments, situations where the need for both the mechanical strength and corrosion resistance features of the material is of utmost importance.

A forged A182 F55 flange has a refined grain structure, stable mechanical properties, and superior performance as a result of the forging process it is compared with cast alternatives; thus, it is a perfect match for industrial systems of the kind that are piping and that are subjected to heavy work.

Material Grade: Super Duplex Stainless Steel UNS S32760 (F55)

UNS S32760 is a super duplex stainless steel with increased chromium, molybdenum, and nitrogen content. When compared to standard austenitic stainless steels such as 304 or 316, F55 has an advantage of providing a much higher strength level as well as an improved resistance to localized corrosion.

Yield strength ≥ 550 MPa, that is more than twice the value of 304/316

An effectively balanced microstructure of ferrite and austenite phases

Engineered for media rich in chlorides and that are aggressive

The advantage of this material is that it allows the designer to lower the thickness of the walls at the same pressure rating, thus, being able to optimize the system weight and cost.

Key Mechanical and Corrosion Resistance Advantages

High Strength for Pressure-Critical Applications

Due to the high yield as well as the tensile strength property, the A182 F55 forged steel flange is a perfect fit in pressure-heavy pipelines, which may be located on a platform offshore or subsea system, where margins of safety are of prime importance.

Excellent Resistance to Chloride Stress Corrosion Cracking

F55 feature one of the major benefits, that is, nearly absolute resistance to chloride-induced stress corrosion cracking (SCC).

F55 is performing very well in these cases where the environment consists of seawater, salt spray or chloride-containing process fluids. It performs much better than regular stainless steel.

Superior Pitting and Crevice Corrosion Resistance

With a PREN value typically between 40–43, calculated as:

PREN = %Cr + 3.3 × %Mo + 16 × %N

This level is significantly higher than:

316L (~25)

Duplex 2205 (~35)

As a result, F55 duplex stainless steel flanges provide reliable long-term service in aggressive environments.

Good Resistance to Uniform Corrosion

The material also shows stable behavior in various acidic and alkaline media, supporting its use in chemical processing systems.

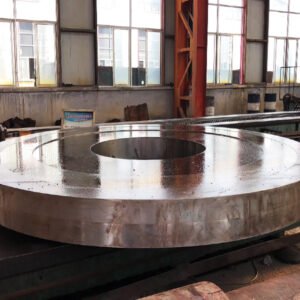

Forging Process and Product Integrity

The forging of a flange plays a critical role in achieving consistent quality.

Compared with cast products, steel forged flanges exhibit:

Dense internal structure

Improved fatigue resistance

Better dimensional stability under pressure and temperature fluctuations

Although terms like forged carbon steel flange or forged carbon steel flanges are common in the flange industry, it is important to clarify that A182 F55 is a forged stainless steel flange, not carbon steel. This distinction matters for corrosion performance and compliance with design specifications.

Weldability and Fabrication Considerations

Modern super duplex grades such as F55 have significantly improved weldability compared with earlier duplex steels.

However, proper welding procedures must be strictly followed to maintain:

Phase balance after welding

Corrosion resistance of welded joints

Controlled heat input and suitable filler materials are essential during fabrication.

Typical Applications of A182 F55 Duplex Stainless Steel Flanges

Marine and Offshore Oil & Gas

Seawater piping systems

Offshore platforms and subsea pipelines

High-pressure, high-salinity environments

Petrochemical and Refining Industry

Sour water handling systems

Chloride-containing process lines

Corrosion-sensitive pipeline connections

Chemical Process Industry

Aggressive chemical transport systems

Acidic and mixed-media process units

These industries rely on forged flanges that deliver both mechanical reliability and long-term corrosion resistance.

Why Choose an A182 F55 Forged Flange

Choosing an ASTM A182 F55 duplex stainless steel flange means prioritizing safety, durability, and lifecycle performance.

Compared with conventional stainless or carbon steel options, F55 forged flanges provide:

Higher strength-to-weight efficiency

Reduced maintenance in corrosive environments

Proven performance in offshore and chemical applications

For projects where operating conditions are severe and failure risk must be minimized, F55 remains a practical and technically sound choice.