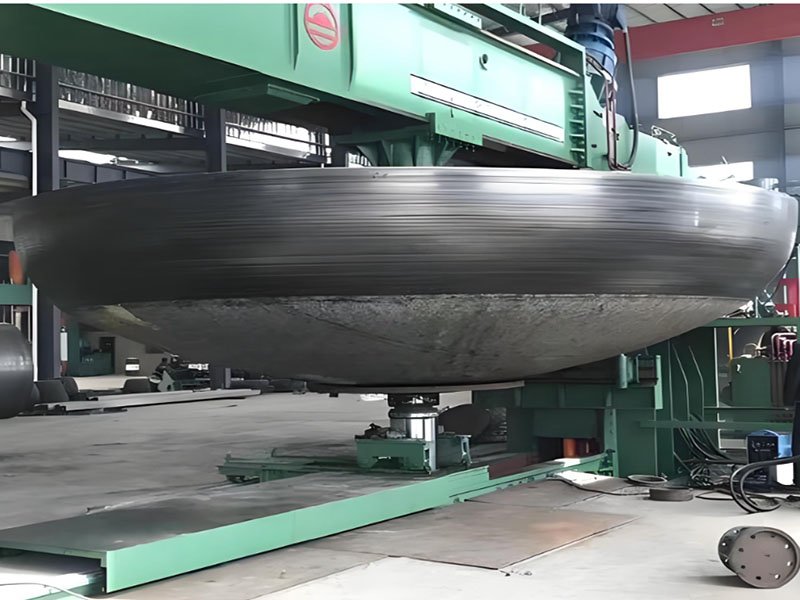

Nuclear Power Plant Head Plate Forgings

Nuclear Power Plant Head Plate Forgings are large, critical forgings installed at the top of the reactor pressure vessel. This metal head plate seals the reactor core, keeps the coolant under high pressure, and isolates radiation. In nuclear engineering, the head plate is regarded as a safety barrier with outstanding structural integrity and fatigue resistance.

Description

What Are Nuclear Power Plant Head Plate Forgings?

Nuclear Power Plant Head Plate Forgings are large, critical forgings installed at the top of the reactor pressure vessel. This metal head plate seals the reactor core, keeps the coolant under high pressure, and isolates radiation. In nuclear engineering, the head plate is regarded as a safety barrier with outstanding structural integrity and fatigue resistance.

Common working conditions demonstrate extreme demands:

Pressure: 15–16 MPa

Temperature: 300–350°C

Design life: ≥ 60 years

A forged metal plate in head offers superior strength and durability compared to cast components. For nuclear applications, forging is the preferred process due to its refined microstructure and long-term safety performance.

Material Grades for Nuclear Head Plates

Material selection is critical. Nuclear Power Plant Head Plate Forgings are produced from high-strength low-alloy nuclear-grade steels, including:

SA-508 Gr.3 Cl.1 (ASME / U.S. Standards)

16MND5 (European Standards)

We also supply special materials when project specifications require unique performance.

For example, a titanium plate for head can be offered for customized radiation shielding or corrosion-resistant applications.

All plates comply with nuclear specifications, ensuring mechanical integrity, radiation resistance, and long service life.

Why Forging Is Required for Nuclear Head Plates

Forging the head plate for nuclear pressure vessels is not optional—it is essential.

Forged head plates provide:

Uniform grain structure

Improved fracture toughness

Outstanding fatigue strength

Excellent resistance to creep, radiation, and high temperature

A metal plate head produced by forging avoids internal defects that can appear in castings.

This ensures long-term stability even after decades of operation.

Function of the Reactor Metal Head Plate

The forged head plate located at the top of the pressure vessel has three core functions:

Sealing the high-pressure coolant inside the reactor environment

Maintaining structural integrity under continuous thermal and mechanical stress

Containing radioactive materials within the reactor core

This metal plate head is a critical safety element. Its failure would directly threaten plant operation and personnel safety. Therefore, strict engineering standards and advanced forging technology are necessary.

Manufacturing & Process Control

To ensure long-term reliability, we apply nuclear-grade manufacturing controls, including:

Advanced ingot and electroslag remelting (ESR) for impurity control

Full material traceability from raw steel to final delivery

Comprehensive non-destructive testing (UT, MT, PT)

Metallurgical evaluation and mechanical property verification

All head plates meet:

ASME

RCC-M

ISO

Project-specific nuclear standards

This rigorous process ensures every head plates forging performs safely during its entire service life.

Service Life of Nuclear Head Plate Forgings

Modern power plants are designed for long operation cycles.

Our forged plate in head products are engineered to match this lifecycle:

Minimum service life: 60 years

Stress, temperature fluctuation, and radiation exposure are fully considered in the design and material selection.

Customized Nuclear Head Forging Solutions

We support complete customization, including:

Plate thickness and diameter

Edge profile and machining

Welding bevels and inspection standards

Material certificates and testing reports

Custom header adapter plates and head plates can be manufactured according to detailed drawings and nuclear safety requirements.

Other Nuclear Forgings We Supply

In addition to Nuclear Power Plant Head Plate Forgings, we supply:

Reactor pressure vessel shells

Forged flange rings

Steam generator forgings

Primary piping forgings

All products are designed for nuclear application and supported by lifelong traceability records.

Conclusion

Nuclear Power Plant Head Plate Forgings are essential for reactor safety.

As a structural sealing component operating under high pressure and radiation, the metal plate in head must achieve exceptional strength, ductility, and long-term reliability.

Through advanced forging technology, refined steel grades, and strict nuclear quality control, we supply high-performance head plates to ensure decades of safe power generation.