Introduction to Nuclear Forgings

Nuclear power plants require components that can withstand high pressure, extreme temperature, and long-term radiation exposure. These challenges make nuclear forgings a preferred solution for pressure vessels, steam generators, reactor internals, turbine shafts, and other safety-critical parts. Unlike standard industrial forgings, nuclear-grade materials must meet strict specifications for quality, toughness, and traceability. The forging process provides uniform microstructure, high strength, and improved fatigue performance, ensuring long service life in demanding nuclear environments.

As a professional Nuclear Forgings Manufacturer, we produce forged components from certified nuclear-grade steels including SA508, SA533, 20MnMoNi55, SA182 and other materials required for nuclear pressure vessels, steam generator shells, forged rings, flanges, and heavy-wall cylindrical parts. All forgings are manufactured with process control, inspection, and documentation that meet nuclear safety and regulatory requirements.

Nuclear-Grade Materials and Manufacturing Standards

Forgings for nuclear applications require compliance with international standards such as ASME Section III, RCC-M, ASTM, EN, and customer-specific specifications. Each step of the manufacturing process—from ingot melting, open-die forging, heat treatment, machining to final inspection—is carefully monitored. The objective is to guarantee mechanical properties, corrosion resistance, and dimensional accuracy for long-term operation.

Typical nuclear-grade steel forgings include:

Reactor pressure vessel forgings

Steam generator rings and shells

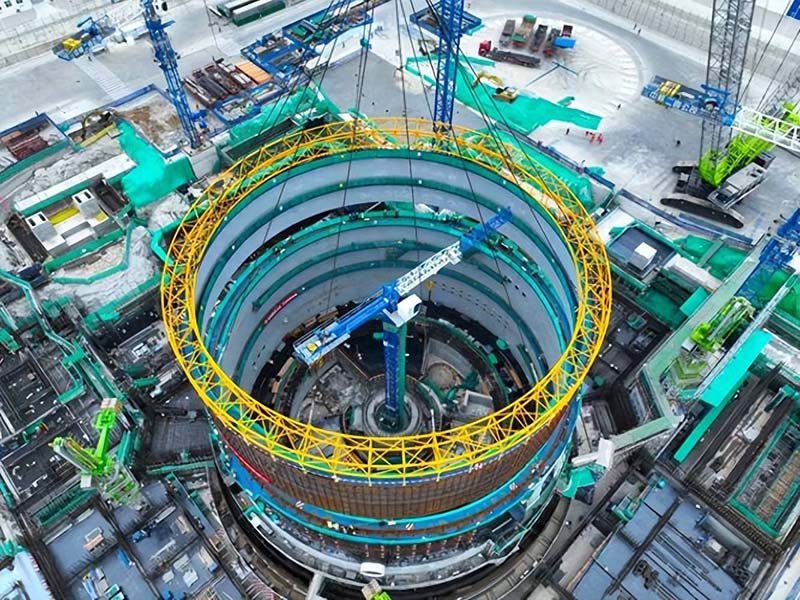

Large ring forgings for containment systems

Heavy-wall pressure components

Nuclear flanges and connectors

The ability to produce large nuclear forgings and maintain metallurgical consistency is essential. This demands high-tonnage forging presses, precision heat treatment, and non-destructive testing techniques such as UT, RT, MT and PT.

Manufacturing Capabilities of TIPTOP

As a professional Nuclear Forgings Manufacturer and Supplier, TIPTOP has developed strong expertise not only in production but also in engineering support for nuclear projects. The factory is equipped with heavy open-die forging presses, ring rolling machines, and multiple heat treatment furnaces, allowing production of large single-piece forgings up to 50 tons.

TIPTOP’s production capability includes:

5,000T and 8,000T hydraulic forging presses

Ring rolling equipment for large diameter components

Controlled heat treatment furnaces

CNC rough and finish machining

In-house non-destructive examination

The manufacturing team consists of experienced engineers specializing in nuclear forging technology, heat treatment, and inspection. Nuclear-grade steel such as SA508, SA533, WB36, 20MnMoNi55 and other alloys are processed with strict control to meet safety requirements and long-term reliability.

Quality Assurance, Documentation, and Traceability

Nuclear projects require transparent quality control and complete traceability. TIPTOP follows a comprehensive quality system that meets ISO9001, ISO14001 and ISO45001. Every forging is traceable back to the original heat number, material certificate, and production record. Final delivery includes full quality documentation:

Chemical composition report

Mechanical properties

Heat treatment records

UT/RT/MT/PT inspection results

Dimensional inspection

Pressure test (when required)

Third-party inspections such are available based on customer requests. This makes TIPTOP a client reliable Nuclear Forgings Supplier .

Application in Nuclear Power Plant Equipment

TIPTOP supplies forged steel components for both new construction projects and replacement parts for operating plants. Our products are used in:

Nuclear reactor pressure vessels

Steam generator shells and tubing supports

Turbine generators

Reactor coolant system components

Containment system rings

Heat exchangers and pumps

Forgings offer excellent resistance to stress corrosion cracking, high fatigue strength, and uniformity, which is essential for safe nuclear operations. With continuously growing demand for nuclear power plant forgings, reliable supply and consistent quality are critical to project execution.

Engineering Support and Technical Collaboration

In addition to manufacturing, TIPTOP provides engineering services that support nuclear project planning. We assist customers with:

Material selection and metallurgy consultation

Finite element deformation simulation

Heat treatment design

Machining allowance planning

Inspection and testing strategy

Close collaboration with customers ensures that every component meets safety and performance expectations. This partnership approach reduces technical risk and helps shorten delivery timelines.

Why Choose TIPTOP for Nuclear Forgings

TIPTOP has built long-term partnerships with nuclear OEMs, power generation companies, and engineering contractors. Customers choose us because:

Proven track record in nuclear-grade forging production

Stable supply chain and large forging capacity

Reliable delivery and technical communication

Comprehensive documentation and traceability

Fast response for spare parts and maintenance demands

Whether for new build, life extension, or outage replacement, TIPTOP ensures safe, consistent, and timely supply of nuclear forgings.

Conclusion

As a trusted Nuclear Forgings Manufacturer, TIPTOP delivers high-quality forged components for reactor pressure vessels, steam generators, turbine systems and containment structures. With strong engineering capability, heavy forging equipment, and complete quality assurance, we support nuclear power plants in achieving safety, reliability, and long operational life.

We continue to invest in technology, material research, and manufacturing processes to meet increasing demand for nuclear pressure vessel forging, nuclear-grade steel forgings, and large nuclear forgings across global markets. Our mission is to provide reliable forged steel solutions for nuclear applications and contribute to the safe development of clean energy.