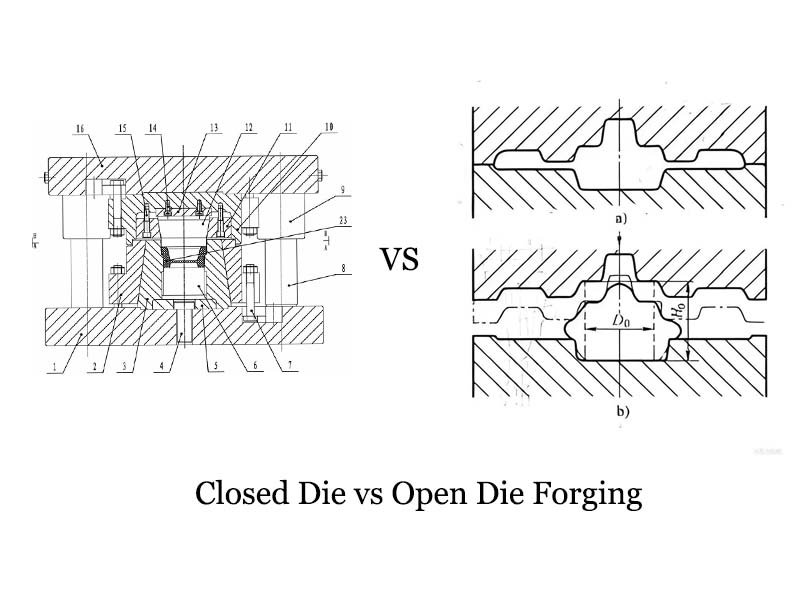

Closed Die vs Open Die Forging: How to Choose the Right Forging Method

In industrial manufacturing, the comparison between closed die vs open die forging is rarely theoretical. It usually starts with a real question: Can this part meet performance and tolerance requirements without unnecessary cost or risk? Understanding how these two forging methods behave in actual production environments is essential for making the right technical and commercial decision.

Closed Die Forging: Process, Advantages, Presses and Applications

Closeddie forging—also known as impression die forging—is a highly productive metal shaping process in which heated metal is worked inside the closed dies to manufacture parts of a definite shape and having good mechanical properties. By forging metal inside a pre-planned die cavity, closed die forging provides a means for producing parts near-net or net-shape with higher strength, better repeatability, and greater dimensional accuracy. As such, the process is a good fit for parts that must perform reliably and be safe.

Forging Manufacturing Process for Heavy-Duty Industrial Components

In heavy industrial fields, the forging manufacturing process is not chosen for convenience. It is selected because the component must survive real working conditions—continuous load, repeated stress, and long service cycles. Whether the part is used in oil and gas equipment, mining machinery, or power transmission systems, forging remains one of the most reliable manufacturing routes.